ASTM A249 TP304/304L/TP316/316L/316Ti Capillary Tube

SSMCT09

Material: 304, 1.4301, X5CrNi18-10; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307;

Get Quote

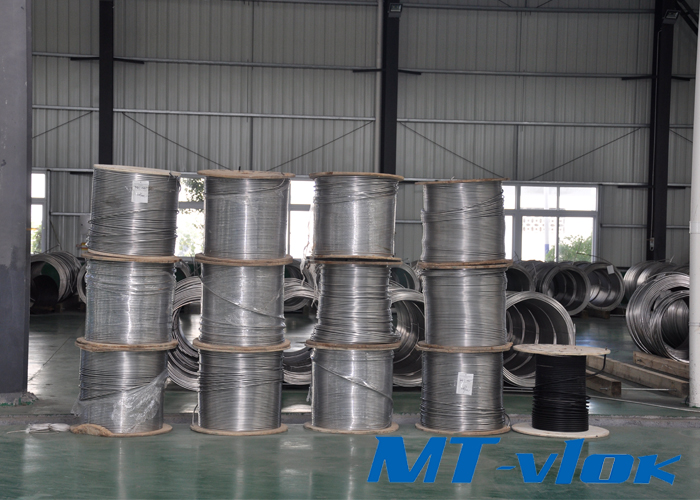

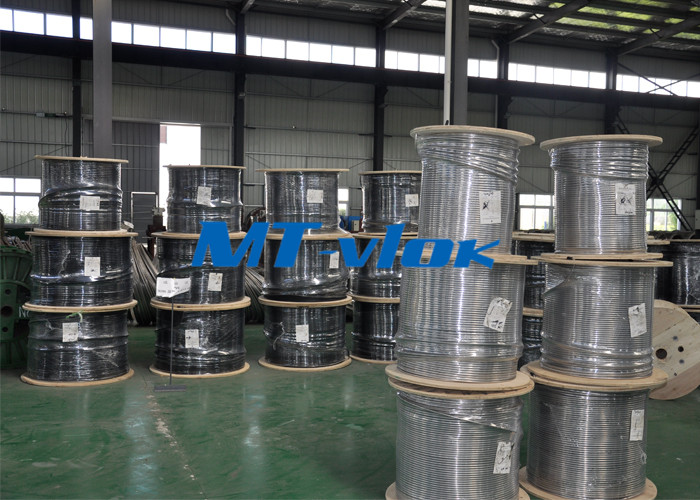

TP304 / 304L 1.4301 / 1.4306 Stainless Steel Welded Single-core Coiled Tube

Ordering code number | ||

| Order Code | Tube Size(O.D×thickness) | Max Pressure(Bar) |

| NYS-1 | 6×1.0 | Working: 180 Bar Test: 270 Bar |

| NYS-2 | 6×1.5 | |

| NYS-3 | 8×1.0 | |

| NYS-4 | 8×1.5 | |

| NYS-5 | 10×1.0 | |

| NYS-6 | 10×1.5 | |

| NYS-7 | 12×1.0 | |

| NYS-8 | 12×1.5 |

Material: 304,304L,316L Thickness: 0.8,1.0,1.2,1.5

Chemical Composition

| C(max) | Si(max) | Mn(max) | P(max) | S(max) | Cr | Ni | Mo | Ti | |

| TP304/1.4301 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-10.5 | ||

| TP304L/1.4307 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | ||

| TP316/1.4401 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |

| TP316L/1.4404 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| Ordering code number | Tube size (O.D x Thickness x Core) | Overall Diameter (.mm) | Sheath Thickness (.mm) | Bundle Weight (kg/M) | Max Pressure (Bar) |

| HTD-1 | 6×1.0×1 | 8 | 1.0 | 0.15 | Working:180Bar

Test:270Bar |

| HTD-2 | 6×1.0×2 | 20 | 2.0 | 0.60 | |

| HTD-3 | 6×1.0×3 | 21 | 2.0 | 0.75 | |

| HTD-4 | 6×1.0×4 | 24 | 2.0 | 0.82 | |

| HTD-5 | 6×1.0×5 | 25 | 2.0 | 0.90 | |

| HTD-6 | 6×1.0×6 | 27 | 2.0 | 1.04 | |

| HTD-7 | 6×1.0×7 | 27 | 2.0 | 1.15 | |

| HTD-8 | 6×1.0×8 | 32 | 2.2 | 1.40 | |

| HTD-9 | 8×1.0×1 | 10 | 1.0 | 0.28 | |

| HTD-10 | 8×1.0×2 | 24 | 1.8 | 0.89 | |

| HTD-11 | 8×1.0×3 | 26 | 2.0 | 1.12 | |

| HTD-12 | 8×1.0×4 | 28 | 2.0 | 1.33 | |

| HTD-13 | 8×1.0×5 | 31 | 2.0 | 1.67 | |

| HTD-14 | 8×1.0×6 | 34 | 2.0 | 2.00 | |

| HTD-15 | 8×1.0×7 | 34 | 2.0 | 2.15 | |

| HTD-16 | 8×1.0×8 | 40 | 2.2 | 2.60 | |

| HTD-17 | 10×1.0×1 | 13 | 1.0 | 0.34 | |

| HTD-18 | 10×1.0×2 | 28 | 1.8 | 1.18 | |

| HTD-19 | 10×1.0×3 | 31 | 2.0 | 1.60 | |

| HTD-20 | 10×1.0×4 | 34 | 2.0 | 1.97 | |

| HTD-21 | 10×1.0×5 | 37 | 2.0 | 2.20 | |

| HTD-22 | 10×1.0×6 | 40 | 2.0 | 2.40 | |

| HTD-23 | 10×1.0×7 | 40 | 2.0 | 2.52 | |

| HTD-24 | 10×1.0×8 | 48 | 2.5 | 3.20 | |

| HTD-25 | 12×1.0×1 | 14 | 1.0 | 0.41 | |

| HTD-26 | 12×1.0×2 | 34 | 2.0 | 1.35 | |

| HTD-27 | 12×1.0×3 | 36 | 2.0 | 1.96 | |

| HTD-28 | 12×1.0×4 | 39 | 2.0 | 2.37 | |

| HTD-29 | 12×1.0×5 | 43 | 2.0 | 2.70 | |

| HTD-30 | 12×1.0×6 | 47 | 2.0 | 3.00 | |

| HTD-31 | 12×1.0×7 | 47 | 2.0 | 3.14 | |

| HTD-32 | 12×1.0×8 | 55 | 2.5 | 3.90 |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Welded / Seamless Coiled Tubing

S31600 / S31603 9.53mm Stainless Steel Welded Super Long Coiled Tube

Material Grade : American Standard TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L Etc European Standard 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 Etc German Standard X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5CrNi17-12-2 , X......

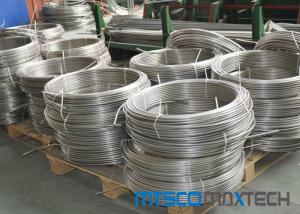

ASTM A269 Seamless Stainless Steel Coiled Tubing Suitable For Pre-insulated Tubing

Material Grade : American Standard: TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L Etc European Standard: 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 Etc German Standard: X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5CrNi17-12-2 , ......

S31803 ASTM A789 / A790 Duplex Steel Coiled Tube For Chemical Industry

Inspection & Test 1 .100 % PMI , Spectro Chemical Aanlysis Test for Raw Material 2 .100 % Dimension & Visual Examination 3 . Mechanical Properties Test Include Tension Test,Flaring Test ( For Seamless tube / pipe ) / Flange Test ( For Welded Pipe & Tube ) , Hardness Test , Reversed Flatteni......

TP316 / 316L / 316Ti Bright Annealed Stainless Steel Seamless Control Line Coiled Tubing

MTSCO is a leading manufacturer who is specialized in seamless coiled tubing produce . Stainless steel seamless coiled tubing final surface is bright annealed. According to standard very strictly, tubes which produced by us always have correct OD and WT tolerance. They are very popular in military, ......Get Quote

*Your email address will not be published. Required fields are marked.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語