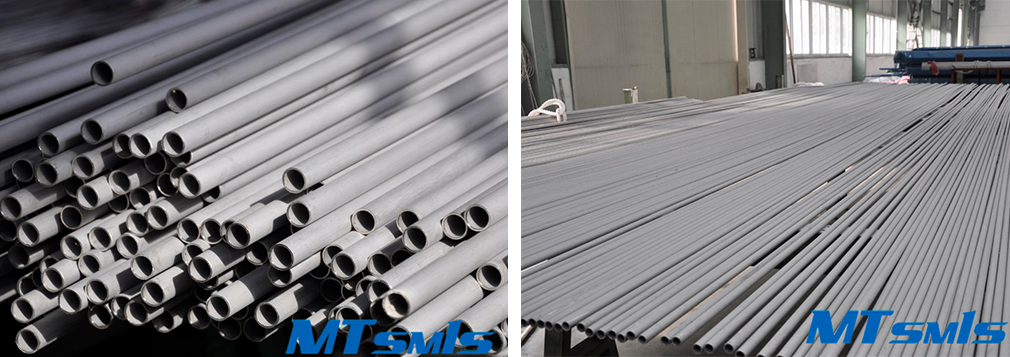

Pressure-Resistant S31803 Tube for Oil & Gas Industry

SSDSP13

Price: From $5000-7000USD/TON

Material: S32205, S31803, 1.4462;

Get Quote

S31803 Pipe/Tube

Parameter Table:

Specifications of S31803 Pipe/Tube | |||

Grade | Standard | Outside Diameter | 3.18mm-38mm |

S31803/2205 | ASTM-A789 | Wall Thickness | 0.5mm-3mm |

Length | ≤30m | ||

Surface | Bright Annealed/ Polished/ Annealed Pickled | ||

Inspection | Appearance/ Dimensional test, PMI; | ||

Certificates | ISO/PED/AD2000/TS/M650 | ||

Package | End protection/ Woven bags/ Wooden cases | ||

Factory advantages and features:

1.HUXIN PIPE - a seamless pipe supplier invested by MTSCO - is a highly reliable seamless steel tube manufacturer with 35 years of pipe making experience.

2. In addition to regular sizes, Huxin can also produce 18m and 25m extension tubes to provide diversified tube specifications.

3. A full range of production and inspection equipment is available, including cold rolling mills, annealing furnaces, pickling tanks, ultrasonic eddy current integration and physical and chemical laboratories.

4.The complete quality control process covers the factory technicians, while the full-time MTSCO quality inspectors control all the links before, during and after production.

5. We have ISO/PED/AD2000 certificates and other certificates.

Introduction to Quality Control Inspection Methods:

Raw Material Quality Assurance

Stringent warranty and PMI checks are conducted on our raw materials, procured from esteemed steel mills like Baosteel and Tsingshan, ensuring their superior quality. Compliance with material specifications is guaranteed through rigorous PMI checks and other meticulous inspections.

Supervised Production Process

Every phase of our seamless tube manufacturing process, including cold rolling, cold drawing, annealing, pickling, and surface treatment, undergoes meticulous oversight. Skilled engineers, equipped with advanced tools, supervise each step, capturing detailed records through photography. Process cards ensure precision and traceability throughout production.

Quality Assurance Prior to Shipment

Our dedicated QC team conducts comprehensive inspections covering appearance, PMI, size, quantity, and more. Mechanical, hardness, ultrasonic, eddy current, and hydraulic tests are performed. Additionally, we invite third-party evaluations (SGS, TUV, BV) and guarantee secure packaging and container reinforcement to maintain product integrity during transportation.

Packing of S31803 Pipe/Tube:

Product | Packing |

LCL PIPE | Plywood crate + protective pipe caps on both ends |

FCL PIPE | Woven bag + protective pipe caps on both ends |

LCL/FCL TUBE | Plywood crate + individual plastic bag wrapping + end caps on both sides |

Material Characteristics and Applications:

S31803 Pipe/Tube is a typical duplex stainless steel pipe, whose metallographic structure is composed of about 50% ferrite and 50% austenite, combining the excellent corrosion resistance of austenitic stainless steel with the high strength characteristics of ferritic stainless steel. The material has excellent resistance to pitting, crevice corrosion and stress corrosion cracking, and is particularly suitable for highly corrosive environments such as chloride ions or seawater. In terms of welding performance, S31803 also performs well, and can maintain duplex balance under controlled processes to ensure stable performance in the weld area. Its yield strength is about twice that of traditional austenitic stainless steel, and it is suitable for occasions with high strength and high corrosion requirements. Common application areas include oil and gas transportation, marine engineering, seawater desalination equipment, chemical equipment, heat exchangers, environmental protection facilities and pulp and paper industry. It is widely used in high temperature, high pressure and harsh working conditions, and is a reliable pipe solution in the industrial field.

Chemical composition:

Steel grade | Physical Property | |||

Y.S | T.S | EL. | HRB | |

S31803 | ≥450 | ≥620 | ≥25 | - |

S32205/2205 | ≥450 | ≥620 | ≥25 | - |

S32750/2507 | ≥550 | ≥800 | ≥15 | ≤32 |

S32760 | ≥550 | ≥750 | ≥45 | ≤29 |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Duplex Steel Seamless Pipe

S32205 / S31803 Big Size Duplex Steel Pipe With Annealed & Pickled Surface For Chemical Industry

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . Duplex describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex......

ASTM A790 / ASTM SA790 S32205 / S31803 F51 Duplex Steel Pipe With PE / BE End

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . Duplex describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex......

1.4462 / 1.4410 Duplex Steel Seamless Pipe, 16 Inch Big Size With Annealed & Pickled Surface

Material Grade: S32205 , S31803 , S32304 , S32750, F51 , F53 , 2205 , 2507 etc Outer Diameter: 10.3mm - 1219mm Wall Thickness: 1.24mm - 59.54mm Length: as per customer’s requirement Standard: ASTM A789 ; ASTM A790 ; EN 10216-5 etc. SAF 2507 / 1.4410 is a super duplex stainless stee......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語