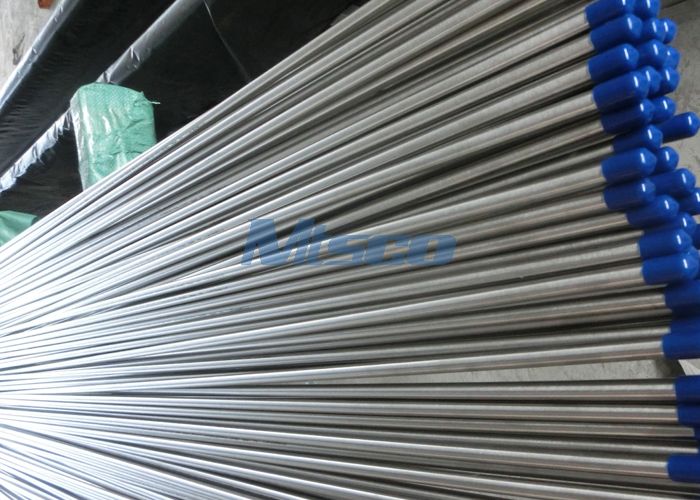

ASTM B829 Inconel 625, 617 Nickel Alloy Seamless Tube

SSNAT17

Price: From $42000-70000USD/TON

Material: Alloy 625, UNSN06625;

Get Quote

ASTM B829 Inc 625 / Inc 617 Nickel Alloy Seamless Tube

Inc 625 Chemical composition:

| % | Ni | Cr | Mo | Fe | C | Mn | Si | P | S | Co | Nb+Ta | Al | Ti |

| min | 58.0 | 20.0 | 8.0 | - | - | - | - | - | - | - | 3.15 | - | - |

| max | - | 23.0 | 10.0 | 5.0 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 1.00 | 4.15 | 0.40 | 0.40 |

Alloy 625 Metallurgical structure:

625 is face-centered cubic lattice structure. Dissolve out the carbon granule and instability quaternary phase, then change it to stability Ni3 (Nb,Ti) trimetric lattice around 650℃ after a long time heat preservation. nickel-chromium content will strength the mechanical performance in the state solution while suppress the plasticity.

Typical application field as below:

1 .The Organic chemical process parts contains chloride, especially in the use of acid chloride catalyst.

2. The digester and bleacherin the use of paper pulp and paper making industry.

3.Absorption tower, re-heater,gas import board, fan, blender, fair water fin, flue and so on for using in flue gas desulfurization system.

4. The equipment and parts in the use of acidic gas environments.

5. Acetic acid and anhydride reaction generator

6. Sulfur acid cooling

6. Sulfur acid cooling

| Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) |

| Package | Iron case; woven bag or as per customer’s requirement |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable |

| Test | NTD(Ultrasonic test, Eddy Current test) |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test) | |

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature) | |

| Chemical Analysis(Photoelectric Emission Spectroscopic) | |

| Market | Europe, Middle East, Southeast Asia, South America. etc |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Bright Annealed Polished Tube

ASTM A269 / A249 TP316 / 31600 Stainless Steel Seamless / Welded Tube For Oil And Gas

Product Description Outer Diameter:3.18-101.6mm Wall Thickness:0.5-20mm NPS:1/8-24 Schedule:5/5S,10/10S,20/20S,40/40S,80/80S,120/120S,160/160S Material Grade:304/304L/316/316L/321/309S/310S, etc Standard:ASTM A269, ASTM A312, etc Application:used in Fluid and Gas Transport, Structure......

ASTM A269 / ASME SA269 TP321 / 321H Stainless Steel Seamless Instrument Tubing

Stainless steel seamless bright annealed tube’s final surface is polished and bright annealed . And the polished grade is includes 180# , 320# , 400# , 600# , 800# . According to standard very strictly , tubes which produced by us always have correct OD and WT tolerance . At instrument industry , b......

10 / 12 / 14SWG Precision Stainless Steel Seamless Tube With Cold Rolled For Medical Industry

MTSCO has the most advanced technology — The floating plug drawing technology which are used in Korea , and equipped with the most environmentally process — Bright annealing process . So our bright annealed precision tube produce technology make us can produce 300 tons high precision tubes every m......Stainless Steel Bright Annealed Straight tubing

Superior Surface Finish The traditional annealing method is performed in a called open furnace, where the atmospheric oxygen causes scaling of the heat treated materials, which makes the surface rough. MTSCO has developed a special bright annealing process, the heat treatment is performed in a so......Get Quote

*Your email address will not be published. Required fields are marked.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語